Thermal spraying

Spray methods

Thermal spraying is a technology of applying metallic, cermet, ceramic and plastic coatings on a properly prepared substrate of the coated element, which has been used in many industries. The main methods of thermal spraying include flame spraying, plasma spraying, arc spraying and supersonic flame spraying (HVOF). Energy sources in the form of a flame, plasma or electric arc are used to heat the coating material (usually in the form of powder or wire) to a liquid state or to melt it. Then the material particles are accelerated and directed by a stream of gases or compressed air onto a properly prepared surface. After impact, they bond with the substrate to form a coating.

Each of the thermal spraying processes has different costs, material possibilities and the related properties of the obtained coatings. The thermal spray technology uses a very large group of materials, is mobile, relatively fast and can be used to obtain protective coatings with a thickness of 50 – 1000 micrometers. Thermal spraying is a group of different processes in which a metallic or ceramic material is deposited on a surface. The main element common to these processes is that in each of them a heat source brings the coating material in the form of powder or wire to a liquid or plastic state, and then it is deposited on the surface of the coated detail. The heat source is electrical or chemical. Depending on the sprayed material and the method used, coatings with adhesion to the substrate of ~80 MPa are obtained and, importantly, the temperature of the substrate on which the coating is sprayed does not exceed 200 degrees C, which means that there is no deformation of the material and no changes in the structure.

Spray types

Flame powder spray

HVDF supersonic spray

Arc spray

Arc spray

Supersonic spray

Supersonic spray

Supersonic spray

Powder flame spraying and layer remelting

Powder flame spraying and layer remelting

Powder flame spraying and layer remelting

Roller table with arc-sprayed coating

Spray methods

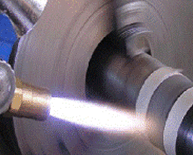

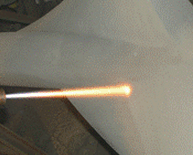

Arc spraying is one of the methods of thermal spraying of coatings, which consists in feeding two wires independently to the head of the gun, where an electric arc is generated between them. The heat from the arc melts the wires. The molten material is sprayed with compressed air and accelerated towards the properly prepared surface of the object. The particles of the material hitting the substrate rapidly solidify, forming a coating.

Material: solid and flux wires

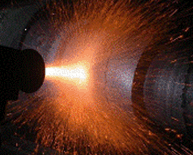

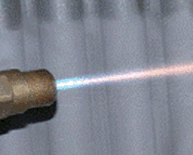

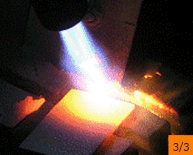

Supersonic spraying is flame spraying. However, compared to conventional flame spraying (LVOF), the HVOF method has a supersonic jet of gases exiting the nozzle. High speed is obtained by feeding a mixture of gases or liquid fuel and oxygen into the combustion chamber of the spray gun, where they are ignited and then continuously burned. The hot gas formed as a result of combustion is “ejected” under high pressure through the nozzle, reaching a speed exceeding the speed of sound (>1000m/s), allowing the particles of the coating material in the form of powder to be accelerated to 800m/s. In another method, a high-pressure nozzle is used – the combustion of the gas mixture takes place outside it. Compressed air is used to focus the beam of sprayed material, which simultaneously cools the nozzle. The fuel can be gaseous (propane, acetylene, natural gas, etc.) or liquid (kerosene, etc.). The powder is fed axially with compressed nitrogen into the gas stream, or injected through a hole in the wall of the nozzle where the pressure is lower. As a result, it reaches high kinetic energy, is melted or melted, and then deposited on the surface of the element, forming a coating.

Material: metallic powders, cermet

Application

Examples of materials used for spraying

Do you want to start a partnership?

Contact with us

Choose proven solutions

Are you looking for a business partner who will have the knowledge and experience needed to achieve your goals? Our team is ready for action! Thanks to our experience in the industry and the continuous expansion of our competences, we are able to offer solutions that will meet your expectations. Together with us you will achieve success!